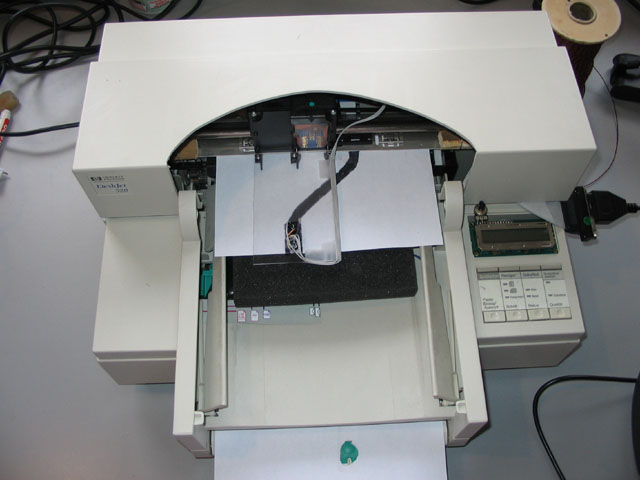

Hidden under plastic cover above the charger plug is a serial port connector. iRobot does not provide support for the serial port, the following quote is from the FAQ section on the iRobot.com website:

Does iRobot provide any codes or specifications for the port?

No, iRobot does not provide this information.

Attempting to alter Roomba’s programming voids the warranty.

Serial Port Specification

The serial port runs at 57600 baud 8N1 with 5 Volt levels. To connect the Roomba port to a PC you have to use a level converter, to convert the 0 and 5 Volt levels of the Roomba port to the approximate -10 and 10 volt levels of the PC port. For level converters see: Simple RS232C Level Converter using Transistors or MAX232 ic.

Serial Connector Pinout

___

|6 7|

/4 5\

\1 2 3/

-- --

pin1 black – microcontroller pin32 (PH7) via 1K resistor R236, internally pulled up to +5V

pin2 brown – GRD

pin3 red – GRD

pin4 orange – microcontroller pin91 (RXD1) via 1K resistor R239

pin5 yellow – microcontroller pin92 (TXD1) via 1K resistor R238 and 100ohm resistor R243

pin6 blue – battery (+15.6volt)

pin7 white – battery (+15.6volt)

Results

Power Connect

Inserting battery pack displays: ( [^C] is control-C character hex 03 )

bl-start[^C]2004-05-26-1037-L [^C]Roomba by iRobot!

MC9S12DP256

2004-07-30-1026-L

battery-current-quiescent-raw 525 battery-current-zero 511

2004-07-30-1026-L

processor-sleep

Hex dump of reply:

0000:62 6C 2D 73 74 61 72 74 bl-start

0008:03 32 30 30 34 2D 30 35 2004-05

0010:2D 32 36 2D 31 30 33 37 -26-1037

0018:2D 4C 20 20 20 03 52 6F -L Ro

0020:6F 6D 62 61 20 62 79 20 omba by

0028:69 52 6F 62 6F 74 21 0D iRobot!

0030:0A 4D 43 39 53 31 32 44 MC9S12D

0038:50 32 35 36 0D 0A 32 30 P256 20

0040:30 34 2D 30 37 2D 33 30 04-07-30

0048:2D 31 30 32 36 2D 4C 20 -1026-L

0050:20 20 0D 0A 62 61 74 74 batt

0058:65 72 79 2D 63 75 72 72 ery-curr

0060:65 6E 74 2D 71 75 69 65 ent-quie

0068:73 63 65 6E 74 2D 72 61 scent-ra

0070:77 20 35 32 35 20 20 62 w 525 b

0078:61 74 74 65 72 79 2D 63 attery-c

0080:75 72 72 65 6E 74 2D 7A urrent-z

0088:65 72 6F 20 35 31 31 0D ero 511

0090:0A 0D 0A 32 30 30 34 2D 2004-

0098:30 37 2D 33 30 2D 31 30 07-30-10

00A0:32 36 2D 4C 20 20 20 0D 26-L

00A8:0A 0D 0A 70 72 6F 63 65 proce

00B0:73 73 6F 72 2D 73 6C 65 ssor-sle

00B8:65 70 0D 0A ep

Power On

Switching power on (turning on green battery led) displays:

key-wakeup

slept for 764 minutes 1091 ticks

2004-07-30-1026-L

battery-current-quiescent-raw 525 battery-current-zero 511

Power Off

Switching power off (turning off green battery led) displays:

processor-sleep

Button Press

Pressing a button on top of the Roomba while power is off displays: (nothing is displayed if power is on)

key-wakeup

slept for 765 minutes 3995 ticks

2004-07-30-1026-L

processor-sleep

Serial Port Pin Input

Grounding pin1 while power is off displays:

key-wakeup

slept for 763 minutes 1841 ticks

2004-07-30-1026-L

device-detect

2004-07-30-1026-L

processor-sleep

Grounding pin1 while power is on displays:

device-detect

2004-07-30-1026-L

Reset via Serial Port

While on, sending control-G resets the roomba as if the battery pack was just inserted:

bl-start[^C]2004-05-26-1037-L [^C]Roomba by iRobot!

MC9S12DP256

2004-07-30-1026-L

battery-current-quiescent-raw 525 battery-current-zero 511

2004-07-30-1026-L

processor-sleep

Charging the Battery

While the battery is being charged the serial port reports every second the charge time, battery voltage, current and temperature. Below is the part of the serial output where the charger is shut off because of reaching the battery temperature limit.

bat: min 240 sec 57 mV 16921 mA 572 deg-C 60

bat: min 240 sec 58 mV 16921 mA 579 deg-C 60

bat: min 240 sec 59 mV 16921 mA 572 deg-C 60

charging-done: temperature max allowed @ minutes 241

do-charging-wait-for-trickle @ minutes 241

bat: min 241 sec 0 mV 16866 mA 26 deg-C 60

bat: min 241 sec 1 mV 16810 mA -27 deg-C 60

bat: min 241 sec 2 mV 16782 mA -27 deg-C 60

Factory Self Test

Hold down Spot and Clean, then press Power briefly and the LED lights will begin to flash. You can now cycle between the diagnostic modes by using Clean to advance in the sequence, and Spot to return to the diagnostic mode before. For more details see: Roomba Red Diagnostic Mode. Below is the output on the serial port during self test/diagnostics:

factory-test 0 leds

wait: false

factory-test 1 bumpers

(bump-left?) PASS

(bump-right?) PASS

factory-test 2 cliffs-side

wiff: cliff-left on 3627 off 3640 signal 13 on? 0

wiff: cliff-front-left on 3628 off 3633 signal 5 on? 1

wiff: cliff-front-right on 3644 off 3644 signal 0 on? 1

wiff: cliff-right on 3644 off 3644 signal 0 on? 1

wiff: wall on 3652 off 3652 signal 0 on? 0

(cliff-left?) PASS

(cliff-right?) FAIL

factory-test 3 cliffs-front

(cliff-front-left?) FAIL

factory-test 4 wheel-drop-and-wall

(wheel-drop?) FAIL

factory-test 5 rcon-receiver

(rcon?)

factory-test 6 battery-sensors

(battery-voltage-ok?) PASS

(battery-temperature-ok?) PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16309 degrees-C 58 PASS

factory-test 7 left-wheel

not left-wheel-stall PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16309 degrees-C 58 PASS

(drive-speed-ok? left forward) PASS

(drive-speed-ok? right stopped) PASS

(left-drive-current-ok?) mA -183 min -326 max -118 mV 16253 degrees-C 58 PASS

not left-wheel-stall PASS

wait: left-wheel-stall

factory-test 8 right-wheel

not right-wheel-stall PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16281 degrees-C 58 PASS

(drive-speed-ok? left stopped) PASS

(drive-speed-ok? right forward) PASS

(right-drive-current-ok?) mA -183 min -326 max -118 mV 16226 degrees-C 58 PASS

not right-wheel-stall PASS

wait: right-wheel-stall

factory-test 9 wheel-encoders

(drive-speed-ok? left stopped) PASS

(drive-speed-ok? right stopped) PASS

(drive-speed-ok? left reverse) PASS

(drive-speed-ok? right reverse) PASS

factory-test 10 stasis

wait: (not (stasis?))

factory-test 11 main-brush

not brush-motor-stall PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16281 degrees-C 58 PASS

(brush-current-ok?) mA -287 min -599 max -241 mV 16226 degrees-C 58 PASS

not brush-motor-stall PASS

wait: brush-motor-stall

factory-test 12 debris

(debris-left?)

factory-test 13 vacuum

not vacuum-motor-stall PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16281 degrees-C 58 PASS

not vacuum-motor-stall PASS

(vacuum-current-ok?) mA -7 min -352 max -176 mV 16281 degrees-C 58 FAIL

factory-test 14 side-brush

not side-brush-motor-stall PASS

(baseline-current-ok?) mA -92 min -202 max -14 mV 16281 degrees-C 57 PASS

not side-brush-motor-stall PASS

(side-brush-current-ok?) mA -7 min -248 max -53 mV 16281 degrees-C 57 FAIL

factory-test 15 int-charger-prep

not (int-charger-available?) PASS

wait: (int-charger-available?)

factory-test 16 int-charger-on

wait: (int-charger-available?)

factory-test 17 int-charger-trickle

wait: (int-charger-available?)

factory-test 18 ext-charger-prep

not (ext-charger-available?) PASS

wait: (ext-charger-available?)

factory-test 19 ext-charger-on

wait: (ext-charger-available?)

factory-test 20 ext-charger-trickle

wait: (ext-charger-available?)

factory-test 21 bootloader

(bootloader-ok?) PASS

factory-test 22 complete

SUMMARY: START

SUMMARY: DATE-TAG 2004-07-30-1026-L

SUMMARY: (baseline-current-ok?) PASS mA -92 min -202 max -14 mV 16281 degrees-C 57

SUMMARY: (left-drive-current-ok?) PASS mA -183 min -326 max -118 mV 16253 degrees-C 58

SUMMARY: (left-drive-stall-current-ok?) untested

SUMMARY: (right-drive-current-ok?) PASS mA -183 min -326 max -118 mV 16226 degrees-C 58

SUMMARY: (right-drive-stall-current-ok?) untested

SUMMARY: (brush-current-ok?) PASS mA -287 min -599 max -241 mV 16226 degrees-C 58

SUMMARY: (brush-stall-current-ok?) untested

SUMMARY: (side-brush-current-ok?) FAIL mA -7 min -248 max -53 mV 16281 degrees-C 57

SUMMARY: (side-brush-stall-current-ok?) untested

SUMMARY: (vacuum-current-ok?) FAIL mA -7 min -352 max -176 mV 16281 degrees-C 58

SUMMARY: (vacuum-stall-current-ok?) untested

SUMMARY: (int-charging-current-ok?) untested

SUMMARY: (int-charging-trickle-current-ok?) untested

SUMMARY: (ext-charging-current-ok?) untested

SUMMARY: (ext-charging-trickle-current-ok?) untested

SUMMARY: (bump-left?) PASS

SUMMARY: (bump-right?) PASS

SUMMARY: (cliff-left?) PASS

SUMMARY: (cliff-right?) FAIL

SUMMARY: (cliff-front-left?) FAIL

SUMMARY: (cliff-front-right?) untested

SUMMARY: (wheel-drop?) FAIL

SUMMARY: (wall?) untested

SUMMARY: (rcon?) FAIL

SUMMARY: (any-remote-opcode?) untested

SUMMARY: (battery-voltage-ok?) PASS

SUMMARY: (battery-temperature-ok?) PASS

SUMMARY: left-wheel-stall PASS

SUMMARY: (drive-speed-ok? left forward) PASS

SUMMARY: (drive-speed-ok? right stopped) PASS

SUMMARY: right-wheel-stall PASS

SUMMARY: (drive-speed-ok? right forward) PASS

SUMMARY: (drive-speed-ok? left stopped) PASS

SUMMARY: (drive-speed-ok? left reverse) PASS

SUMMARY: (drive-speed-ok? right reverse) PASS

SUMMARY: (stasis?) untested

SUMMARY: brush-motor-stall PASS

SUMMARY: (debris-left?) FAIL

SUMMARY: (debris-right?) untested

SUMMARY: vacuum-motor-stall PASS

SUMMARY: side-brush-motor-stall PASS

SUMMARY: (int-charger-available?) PASS

SUMMARY: (ext-charger-available?) PASS

SUMMARY: (bootloader-ok?) PASS

SUMMARY: END